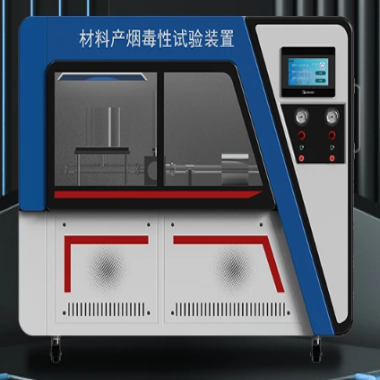

Floor Material Burning Performance Tester

Category:Material strength tester

Introduction

The floor coverings flammability tester is used to tester a variety of flooring materials, such as: textile carpets, cork, wood, rubber and plastic flooring and floor spray materials. The results can reflect the combustion properties of the floor material (including the substrate), which is used in the test combustion chamber to ignite the floor material placed horizontally and exposed to the tilted thermal radiation field with a small flame. It can be used to evaluate the material flame Communication ability.

Standards

ASTM E648-15 Standard test method for critical radiant flux of floor-covering systems using radiant heat energy source

BS EN ISO 9239-1-2010 Reaction to fire test for flooring-Part 1: Determination of the burning behavior using a radiant heat source

GB/T 11785-2005 Determination of Combustion Performance -Floor material radiation heat source method

Features

The main components are imported, which is safe and reliable, long service life;

Gas pipeline layout is reasonable, equipped with gas leakage and tempering device. The instrument automatically closes at the inlet of gas leakage, and alarm;

Radiant plate temperature can be automatically adjusted.

Propane gas supply is equipped with imported mass flow controller. The air output is equipped with a separate blower. Automatic adjustment of the frequency without manual;

Normal test, the flame spread distance can be recorded through the foot switch, without the need to manually click the mouse to operate the computer;

Instrument with industrial one machine, is easy to operate and reliable;

The instrument adopts advanced control software developed by VB language. Centralized control acquisition and processing data analysis;

Technical Parameters

| Radiant heat source | Radiation surface size (300 × 450) mm ± 10mm, Radiation plate withstands ≤ 900 °C |

| Specimen fixture | L-shaped stainless steel (2.0 ± 0.1) mm, Exposed area (200 ± 3)mm × (1015 ± 10)mm |

| Igniter | Stainless steel with: 19 Ø0.7mm holes @0°, 16 Ø0.7mm holes @60° |

| Propane rotor flow | (0.026 ± 0.002) L/s, Flame height 60-120 mm |

| Power supply | AC380V 3-phase 5-wire |

| Smoke removal rate | 2.5 ± 0.2 m/s |

| Smoke capacity | 39-85 m³/min |

| Heat flux meter | Range: 0-15 kW/m², Accuracy: <±3% |

| Temperature sensor | 2 K-type thermocouples (Ø3.2mm), Installed @ 150 ± 2mm |

| Radiation pyrometer | 480-530 °C range, ±0.5 °C, 1.4m distance, 1-9μm wavelength |